Geometric Dimensioning and Tolerancing

with Y14.5M-1994

Geometric Dimensioning and Tolerancing (GDT) was developed as an international language to communicate exactly how a part should be made to achieve the required functionality. When properly applied, GDT is a powerful tool for achieving quality and for reducing costs in design, manufacturing, and inspection.

The American Society of Mechanical Engineers (ASME) document Y14.5M-1994 Dimensioning and Tolerancing (Reaffirmed 2004) continues to be a widely used U.S. standard on this language. Our On-Site Seminar Geometric Dimensioning and Tolerancing with Y14.5M-1994, provides in-depth information on the use and

interpretation of this important standard.

The Seminar is designed for presentation to a mixed audience of Engineering, Manufacturing, Purchasing, and Quality Department personnel. The program can be customized to meet the specific needs of:

Geometric Dimensioning and Tolerancing with Y14.5M-1994 consists of 16 instructional units and requires approximately 32 to 40 hours for presentation. Participants receive a Seminar Binder containing copies of all presentation materials, copies of selected illustrations, reprints of key articles and technical papers, and additional materials.

Various presentation schedules are available to meet your specific requirements.

Please contact us to learn how you can put the power of Geometric Dimensioning and Tolerancing to work for your company.

To download the data sheet for this program, please click here. (PDF)

Note: For companies implementing ASME Y14.5-2009 instead, please see the page for our On-Site Seminar Geometric Dimensioning and Tolerancing with Y14.5-2009.

Seminar Outline:

Unit 1 - Background

![]() • Introduction

• Introduction

![]() • References

• References

![]() • Definitions

• Definitions

![]() • Fundamental Rules

• Fundamental Rules

![]() • Units of Measurement

• Units of Measurement

![]() • Types of Dimensioning

• Types of Dimensioning

![]() • Application of Dimensions

• Application of Dimensions

![]() • Dimensioning Features

• Dimensioning Features

![]() • Location of Features

• Location of Features

Unit 2 - General Tolerancing

![]() • Direct Tolerancing Methods

• Direct Tolerancing Methods

![]() • Tolerance Expression

• Tolerance Expression

![]() • Interpretation of Limits

• Interpretation of Limits

![]() • Single Limits

• Single Limits

![]() • Tolerance Accumulation

• Tolerance Accumulation

![]() • Limits of Size

• Limits of Size

![]() • Applicability of RFS, MMC, and LMC

• Applicability of RFS, MMC, and LMC

![]() • Screw Threads

• Screw Threads

![]() • Gears and Splines

• Gears and Splines

![]() • Virtual/Resultant Condition

• Virtual/Resultant Condition

![]() • Angular Surfaces

• Angular Surfaces

![]() • Conical Tapers

• Conical Tapers

![]() • Flat Tapers

• Flat Tapers

![]() • Radius

• Radius

![]() • Statistical Tolerancing

• Statistical Tolerancing

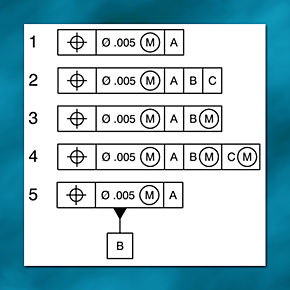

Unit 3 - Symbology

![]() • Use of Notes to Supplement Symbols

• Use of Notes to Supplement Symbols

![]() • Symbol Construction

• Symbol Construction

![]() • Geometric Tolerance Symbols

• Geometric Tolerance Symbols

![]() • Feature Control Frame Placement

• Feature Control Frame Placement

![]() • Identification of the Tolerance Zone

• Identification of the Tolerance Zone

![]() • Tabulated Tolerances

• Tabulated Tolerances

Unit 4 - Datums

![]() • Immobilization of Part

• Immobilization of Part

![]() • Datum Features

• Datum Features

![]() • Specifying Datum Features in a Order of

• Specifying Datum Features in a Order of

![]() Precedence

Precedence

![]() • Establishing Datums

• Establishing Datums

![]() • Datum Targets

• Datum Targets

Unit 5 - Positional Tolerancing

![]() • Positional Tolerancing

• Positional Tolerancing

![]() – Method

– Method

![]() – Application to Base Line and Chain

– Application to Base Line and Chain

![]() Dimensioning

Dimensioning

![]() • Fundamental Explanation of Positional

• Fundamental Explanation of Positional

![]() Tolerancing

Tolerancing

![]() – Material Condition Basis

– Material Condition Basis

![]() – MMC as Related to Positional Tolerancing

– MMC as Related to Positional Tolerancing

![]() – Zero Positional Tolerance at MMC

– Zero Positional Tolerance at MMC

![]() – RFS as Related to Positional Tolerancing

– RFS as Related to Positional Tolerancing

![]() – LMC as Related to Positional Tolerancing

– LMC as Related to Positional Tolerancing

![]() – Multiple Patterns of Features Located by

– Multiple Patterns of Features Located by

![]() Basic Dimensions Relative to Common

Basic Dimensions Relative to Common

![]() Datums

Datums

Unit 6 - Feature Pattern Positional Tolerancing

![]() • Composite Positional Tolerancing

• Composite Positional Tolerancing

![]() • Projected Tolerance Zone

• Projected Tolerance Zone

![]() • Nonparallel Holes

• Nonparallel Holes

![]() • Counterbored Holes

• Counterbored Holes

![]() • Closer Control at One End of a Feature

• Closer Control at One End of a Feature

![]() • Bidirectional Positional Tolerancing of

• Bidirectional Positional Tolerancing of

![]() Features

Features

Unit 7 - Other Positional Tolerancing

![]() • Noncircular Features

• Noncircular Features

![]() • Coaxiality Controls

• Coaxiality Controls

![]() • Concentricity

• Concentricity

![]() • Positional Tolerancing for Symmetrical

• Positional Tolerancing for Symmetrical

![]() Relationships

Relationships

![]() • Symmetry Tolerancing to Control the Median

• Symmetry Tolerancing to Control the Median

![]() Points of Opposed or Correspondingly

Points of Opposed or Correspondingly

![]() Located Elements of Features

Located Elements of Features

![]() • Spherical Features

• Spherical Features

Unit 8 - Form Tolerancing

![]() • Form and Orientation Control

• Form and Orientation Control

![]() • Specifying Form and Orientation Tolerances

• Specifying Form and Orientation Tolerances

![]() • Form Tolerances

• Form Tolerances

![]() – Straightness

– Straightness

![]() – Flatness

– Flatness

![]() – Circularity (Roundness)

– Circularity (Roundness)

![]() – Cylindricity

– Cylindricity

Unit 9 - Profile Tolerancing

![]() • Profile Control

• Profile Control

![]() – Profile Tolerancing

– Profile Tolerancing

![]() – Tolerance Zone

– Tolerance Zone

![]() – Explanation of Profile Tolerance

– Explanation of Profile Tolerance

![]() – Application of Datums

– Application of Datums

![]() – Combined Controls

– Combined Controls

![]() – Coplanarity

– Coplanarity

![]() – Profile Tolerance for Plane Surfaces

– Profile Tolerance for Plane Surfaces

![]() – Profile Tolerance for a Conical Feature

– Profile Tolerance for a Conical Feature

![]() – Composite Profile

– Composite Profile

Unit 10 - Orientation Tolerancing

![]() • Specifying Orientation Tolerances in Relation

• Specifying Orientation Tolerances in Relation

![]() to Datum Features

to Datum Features

![]() • Angularity

• Angularity

![]() • Parallelism

• Parallelism

![]() • Perpendicularity

• Perpendicularity

Unit 11 - Runout Tolerancing

![]() • Runout Tolerance

• Runout Tolerance

![]() • Free State Variation

• Free State Variation

Unit 12 - Principal Changes and Improvements

Unit 13 - Formulas for

Positional Tolerancing

![]() • Formula Symbols

• Formula Symbols

![]() • Floating Fastener Case

• Floating Fastener Case

![]() • Fixed Fastener Case When Projected

• Fixed Fastener Case When Projected

![]() Tolerance

Zone is Used

Tolerance

Zone is Used

![]() • Provision for Out-of-Squareness When

• Provision for Out-of-Squareness When

![]() Projected

Tolerance is Not Used

Projected

Tolerance is Not Used

![]() • Coaxial Features

• Coaxial Features

![]() • Limits and Fits

• Limits and Fits

Unit 14 - Form, Proportion, and

Comparison of Symbols

Unit 15 - Former Practices

![]() • Definition for Feature of Size

• Definition for Feature of Size

![]() • Applicability of RFS, MMC, and LMC

• Applicability of RFS, MMC, and LMC

![]() • Tangent Radii

• Tangent Radii

![]() • Datum Feature Symbol

• Datum Feature Symbol

![]() • Projected Tolerance Zone

• Projected Tolerance Zone

Unit 16 - Decision Diagrams for Geometric Control

![]() • Purpose

• Purpose

![]() • Functional Requirements

• Functional Requirements

![]() • Reference to Standard

• Reference to Standard

![]() • Geometric Controls

• Geometric Controls

![]() • Choosing Other Controls

• Choosing Other Controls

![]() • Use of Modifiers

• Use of Modifiers

![]() • Datums

• Datums

Secrets of Marketing | Intro to ISO 9000 | ISO 9001 Int. Auditing | Implementing Six Sigma

Send mail to websupport@iplusnet.com with questions or comments about this web site.

Copyright © 2024 by Innovations PLUS. All rights reserved.