Implementing Statistical Process Control

Since the early 1980’s major corporations have often mandated the use of Statistical Process Control (SPC) techniques for both internal and Supplier operations. When implemented correctly, SPC can be a powerful tool for achieving quality and productivity. The key to success with SPC is in knowing when, where, and how it should be used.

Implementing Statistical Process Control is an in-depth seminar program covering all of the basic tools and techniques of SPC. Beyond this, it cover the critical business and management issues faced by companies trying to start, improve, or expand a SPC program.

This Seminar is oriented toward Managers, Supervisors, Engineers, and Quality Professionals. Participants need not have any previous training in SPC. The content can be customized to meet the needs of specific departments or personnel.

Implementing Statistical Process Control is divided into four major sections and requires approximately 32 hours for presentation. Various presentation schedules are available to meet your requirements.

Seminar participants receive copies of Learner Handbooks and Learner Workbooks for each section, a statistical calculator, and additional materials.

Please contact us to find out how to succeed with SPC at your company.

To download the data sheet for this program, please click here. (PDF)

Seminar Outline:

Section 1 - Introduction to SPC

Unit 1 - Introduction to SPC

![]() • Statistical Process Control

• Statistical Process Control

![]() • Process Variation

• Process Variation

![]() – Common Causes

– Common Causes

![]() – Assignable Causes

– Assignable Causes

![]() • Quality Characteristics

• Quality Characteristics

![]() – Variables

– Variables

![]() – Attributes

– Attributes

![]() • Distributions

• Distributions

![]() – Population

– Population

![]() – Samples

– Samples

![]() – Distribution

– Distribution

Unit 2 - Frequency Tables

![]() • Frequency Table

• Frequency Table

![]() • Variables Data Form

• Variables Data Form

![]() – Zero Value

– Zero Value

![]() – Unit of Measure

– Unit of Measure

![]() – Recorded Value

– Recorded Value

![]() • Labeling Frequency Tables

• Labeling Frequency Tables

![]() • Recording Measurement Values

• Recording Measurement Values

![]() • Recording Frequency of Occurrence

• Recording Frequency of Occurrence

![]() • Recording Cumulative Frequency

• Recording Cumulative Frequency

![]() • Recording Cumulative Percent

• Recording Cumulative Percent

![]() • Cell Width

• Cell Width

Unit 3 - Histograms

![]() • Histograms

• Histograms

![]() • Labeling Histograms

• Labeling Histograms

![]() • Constructing Histogram Bars

• Constructing Histogram Bars

Unit 4 - Probability Plots

![]() • Probability Plots

• Probability Plots

![]() • Lower Percentage Scale

• Lower Percentage Scale

![]() • Upper Percentage Scale

• Upper Percentage Scale

Unit 5 - Mean and Standard

Deviation

![]() • Mean

• Mean

![]() • Standard Deviation

• Standard Deviation

![]() • Population Mean

• Population Mean

![]() • Population Standard Deviation

• Population Standard Deviation

![]() • Sample Mean

• Sample Mean

![]() • Sample Standard Deviation

• Sample Standard Deviation

Unit 6 - Control Charts

![]() • Control Charts

• Control Charts

![]() • Subgroups

• Subgroups

![]() • Mean

• Mean

![]() • Range

• Range

![]() • Upper and Lower Control Limits

• Upper and Lower Control Limits

![]() • Common Causes

• Common Causes

![]() • Assignable Causes

• Assignable Causes

![]() • Types of Control Charts

• Types of Control Charts

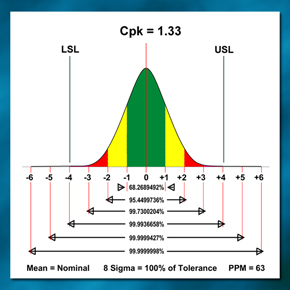

Unit 7 - Process Capability

![]() • Histogram Method

• Histogram Method

![]() – Capability Ratio

– Capability Ratio

![]() – Capability Index

– Capability Index

![]() • Normal Probability Plot Method

• Normal Probability Plot Method

![]() • Process Capability Studies

• Process Capability Studies

Unit 8 - Actions and Options

![]() • In Statistical Control and Capable

• In Statistical Control and Capable

![]() • In Statistical Control and Incapable

• In Statistical Control and Incapable

![]() • Out of Statistical Control and Capable

• Out of Statistical Control and Capable

![]() • Out of Statistical Control and Incapable

• Out of Statistical Control and Incapable

![]() • Options

• Options

![]() • Summary

• Summary

Section 2 - Variables Control Charts

Unit 1 - Introduction

![]() • Process Capability

• Process Capability

![]() – Variables Control Charts

– Variables Control Charts

![]() • Review of Control Chart Theory

• Review of Control Chart Theory

Unit 2 - Types of Control

Charts

![]() • Types of Control Charts

• Types of Control Charts

![]() • Process Capability Studies

• Process Capability Studies

Unit 3 - Collecting Variables

Data

![]() • Selecting Characteristics to be Charted

• Selecting Characteristics to be Charted

![]() • Determining the Subgroup Size

• Determining the Subgroup Size

![]() • Determining the Sampling Interval

• Determining the Sampling Interval

Unit 4 - Starting the X Bar and

R Chart

![]() • Collecting the Data

• Collecting the Data

![]() – Zero Value

– Zero Value

![]() – Unit of Measure

– Unit of Measure

Unit 5 - Calculations

![]() • X Bar - Subgroup Average

• X Bar - Subgroup Average

![]() • R - Subgroup Range

• R - Subgroup Range

![]() • X Double Bar - Grand Average

• X Double Bar - Grand Average

![]() • R Bar - Average Range

• R Bar - Average Range

![]() • Labeling the Charts

• Labeling the Charts

![]() • Plotting Points

• Plotting Points

![]() • Upper and Lower Control Limits

• Upper and Lower Control Limits

Unit 6 - Interpreting Patterns

![]() • Natural Patterns

• Natural Patterns

![]() • Unnatural Patterns

• Unnatural Patterns

![]() • Outliers

• Outliers

![]() • Runs

• Runs

![]() • Sudden Change in Level

• Sudden Change in Level

![]() • Mixtures

• Mixtures

![]() • Trends

• Trends

Unit 7 - Determining Process

Capability

![]() • Capability Index

• Capability Index

![]() • Capability Ratio

• Capability Ratio

![]() • Centering the Process

• Centering the Process

Section 3 - Attributes Control Charts

Unit 1 - Introduction

![]() • Quality Characteristics

• Quality Characteristics

![]() • Conformance to Specifications

• Conformance to Specifications

![]() • Defect

• Defect

![]() • Defective

• Defective

![]() • Nonconformities

• Nonconformities

![]() • Nonconforming Units

• Nonconforming Units

![]() • Review of Control Chart Theory

• Review of Control Chart Theory

![]() • Process Capability Study

• Process Capability Study

Unit 2 - Types of Attribute

Control Charts

![]() • Selecting Which Control Chart to Use

• Selecting Which Control Chart to Use

![]() • Creating Attribute Control Charts

• Creating Attribute Control Charts

![]() • Determining the Subgroup Size and

• Determining the Subgroup Size and

![]() Sampling Interval

Sampling Interval

![]() • Constructing the Control Charts

• Constructing the Control Charts

![]() • Plotting the Data

• Plotting the Data

Unit 3 - Constructing p Charts

Unit 4 - Constructing np Charts

Unit 5 - Constructing c Charts

Unit 6 - Constructing u Charts

Unit 7 - Types of Patterns

![]() • Natural Patterns

• Natural Patterns

![]() • Unnatural Patterns

• Unnatural Patterns

![]() • Outliers

• Outliers

![]() • Runs

• Runs

![]() • Sudden Change in Level

• Sudden Change in Level

![]() • Mixtures

• Mixtures

![]() • Trends

• Trends

Unit 8 - Determining Process

Capability

Section 4 - Implementing SPC

Unit 1 - Implementing SPC

![]() • Introduction

• Introduction

![]() • Training

• Training

![]() • Where to Use SPC

• Where to Use SPC

![]() • Choosing Between Variables and Attributes

• Choosing Between Variables and Attributes

![]() Methods

Methods

![]() • Measurement Variability

• Measurement Variability

![]() • Actions based on Capability Determination

• Actions based on Capability Determination

![]() • Establishing Standard Values for Control

• Establishing Standard Values for Control

![]() Charts

Charts

Unit 2 - Cause and Effect

Diagrams

![]() • Cause Enumeration Diagram

• Cause Enumeration Diagram

![]() • Dispersion Analysis Diagram

• Dispersion Analysis Diagram

![]() • Process Analysis Diagram

• Process Analysis Diagram

![]() • Brainstorming Sessions

• Brainstorming Sessions

![]() • Making a Cause Enumeration Diagram

• Making a Cause Enumeration Diagram

![]() • Making a Dispersion Analysis Diagram

• Making a Dispersion Analysis Diagram

![]() • Making a Process Analysis Diagram

• Making a Process Analysis Diagram

Unit 3 - Making and Using Cause

and Effect Diagrams

![]() • Cause and Effect Diagrams

• Cause and Effect Diagrams

![]() • Cause and Effect Diagram Summary

• Cause and Effect Diagram Summary

Unit 4 - Pareto Diagrams

![]() • Pareto Diagrams

• Pareto Diagrams

![]() • Pareto Diagram Summary

• Pareto Diagram Summary

Unit 5 - Automating SPC

![]() • Calculators

• Calculators

![]() • Smart Instruments

• Smart Instruments

![]() • Stand-Alone Systems

• Stand-Alone Systems

![]() • Computers

• Computers

Unit 6 - Designed Experiments

![]() • Regression Analysis

• Regression Analysis

![]() • Linear Regression

• Linear Regression

![]() • Making a Scatter Diagram

• Making a Scatter Diagram

![]() – Scatter Diagram

– Scatter Diagram

![]() – Negative Correlation

– Negative Correlation

![]() – Positive Correlation

– Positive Correlation

![]() • Summary

• Summary

Secrets of Marketing | Intro to ISO 9000 | ISO 9001 Int. Auditing | Implementing Six Sigma

Send mail to websupport@iplusnet.com with questions or comments about this web site.

Copyright © 2024 by Innovations PLUS. All rights reserved.